Oil seal is the customary name for general seals, which is simply the seal of lubricating oil. It is a mechanical component used to seal grease (oil is the most common liquid substance in the transmission system, and is also generally referred to as the general liquid substance). It isolates the parts that need to be lubricated in the transmission parts from the output parts so that the lubrication Oil leakage. The seals used for static seals and dynamic seals (generally reciprocating motion) are called oil seals.

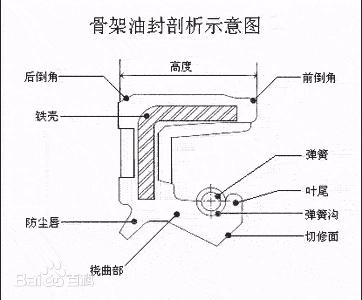

The representative form of the oil seal is the TC oil seal, which is a double-lip oil seal with a self-tightening spring that is completely covered by rubber. Generally speaking, the oil seal often refers to this TC skeleton oil seal.

Oil seals are generally divided into single types and assembled types. The assembled type is that the skeleton and lip materials can be freely combined, and are generally used for special oil seals [2].

The sealing function, characteristics, structure type, working state, and sealing mechanism of the oil seal, can be divided into various forms and different names, but it is customary to call the lip seal ring of the rotating shaft oil seal, static seal, and dynamic seal (generally reciprocating motion). ) with a seal called a seal [2].

The representative form of the oil seal is the TC oil seal, which is a double-lip oil seal with a self-tightening spring completely covered by rubber. Generally speaking, the oil seal often refers to this TC skeleton oil seal. The schematic diagram of the skeleton oil seal is shown in the figure.

Material:

Common materials for oil seals are nitrile rubber, fluorine rubber, silicone rubber, acrylate rubber, polyurethane, PTFE, etc.

Nitrile rubber (NBR)

It has a good heat resistance and wear resistance, and is resistant to various lubricating oils, greases, oil and gas mixtures, etc., and is suitable for temperatures ranging from -30 to 120 degrees Celsius, but it cannot be used in phosphate ester hydraulic oils and gear oils containing extreme pressure additives. It is stable in gasoline and low aniline point mineral oil.

Polyacrylate Rubber (ACM)

Excellent oil resistance, heat resistance, wear resistance, ozone resistance, UV radiation resistance, especially resistant to extreme pressure fluids containing lubricating oil, gear oil, motor oil, motor oil, petroleum hydraulic oil, etc., suitable for -30~150 degrees Celsius scope work.

fluoro rubber

Aging resistance, heat resistance, oil resistance, suitable for almost all lubricating oil, fuel oil, gasoline, not easy to harden in oil containing extreme pressure additives, but poor cold resistance, high temperature wear resistance, large permanent compression deformation, suitable for At temperature -20~250 degrees Celsius.

Silicone Rubber

With outstanding high and low-temperature resistance, it can be used for a long time at 150 degrees Celsius without performance changes; it can be used continuously for 10,000 hours at 200 degrees Celsius and can maintain its unique use flexibility and ozone resistance and resistance in the working temperature range of -70~260 degrees Celsius. weather and other advantages.

Teflon

It has outstanding chemical stability, thermal stability, friction reduction, and self-lubrication, and its cracking temperature is above 400. Therefore, it can work normally in the temperature range of -200~300 degrees Celsius. In addition to free fluorine and alkali metals, it has excellent corrosion resistance to chemicals, solvents, hydroxide compounds, and acids.

Nitrile rubber and fluoro rubber materials are widely used oil seals. The former has low cost, but the temperature resistance and sealing performance are significantly improved, but the cost is high, and it still has some bad commonalities of ordinary rubber materials, such as poor wear resistance. , short service life, particularly sensitive to the eccentric response of the shaft, etc., leakage is still relatively common. PTFE oil seal is a product with high technical content, and it is the direction of oil seal development in the future.

When selecting the material of the oil seal, the compatibility of the material to the working medium, the adaptability to the working temperature range, and the ability of the lip to follow the rotating shaft at high speed must be considered. Generally, when the oil seal is working, the temperature of its lip is 20~50℃ higher than the temperature of the working medium, so it should be paid attention to when selecting the oil seal material. The working range of the oil seal is related to the material used for the oil seal: -40~120℃ when the material is nitrile rubber (NBR), -30~180℃ for acrylic rubber (ACM), and -25~300℃ for fluorine rubber (FPM).

Function:

Engine: Crankshaft--Crankshaft front and rear oil seal valve--valve oil seal (engine repair kit o-ring) (distributor oil seal, water pump oil seal, balance shaft oil seal, oil pump oil seal...); Camshaft--Camshaft oil seal ; Transmission: Transmission--transmission front and rear oil seals, shift lever oil seal (transmission repair kit o-ring) (transfer case--transfer case front and rear oil seals); Rear axle: half shaft--rear half shaft oil seal difference Gearbox -- (front) rear angle vector oil seal, rear wheel oil seal, front wheel oil seal, direction oil seal (steering machine repair kit o-ring), steering booster oil seal (front axle oil seal).

All parts that have liquid lubricating oil in the running body box and are connected to the outside need oil seals. Some are rubber, some are metal, and most are steel rubber, such as crankshaft rear oil seal, gearbox front and rear oil seals, left and right half shaft oil seals, main reducer front oil seals, air compressor crankshaft oil seals, etc.

Oil seal design:

Ordinary single lip B (SC)

Generally used for high and low-speed rotating shafts and reciprocating motion to seal mineral oil and water and other media.

Ordinary oil seals are used in the case of less dust and impurities. When the medium pressure is less than 0.05MPa, the maximum linear speed is 15m/s, and the reciprocating speed is less than 0.1m/s [3].

Ordinary double lip FB (TC)

In addition to the use characteristics of the S-type oil seal described above, it can also be dust-proof.

Ordinary oil seal with dust lip can prevent dust. When the medium pressure is less than 0.05MPa, the linear speed is less than or equal to 15m/s.

Springless BV

Springless single lip type skeleton rubber oil seal.

Generally suitable for low-speed conditions, the sealing medium is a lubricating ester. Linear speed≤6m/s.

Exoskeleton single lip W

Single lip exposed skeleton rubber oil seal with spring, thin waist, good followability, and good rigidity.

Ordinary oil seals are used when there is less dust and impurities, and the medium pressure is less than 0.05MPa. When the rotational axis speed is less than or equal to 15m/s.

Exoskeleton Double Lips FW

Double lip exposed skeleton rubber oil seal with auxiliary lip, thin waist, good followability, high rigidity, and good coaxiality.

Ordinary oil seal with dust lip can be dustproof, and the medium pressure is less than 0.05MPa. Speed ≤ 15m/s.

Assembled single lip FZ

The outer skeleton oil seal is assembled from the inner and outer skeleton and has the characteristics of high installation accuracy, fast heat dissipation, and heavy load.

It is suitable for heavy-duty working conditions under high temperature and high speed, medium pressure ≤ 0.05MPa, and maximum linear speed ≤ 15m/s .

One-way reflux type right-handed SR, left-handed DL

There are oblique ribs with an angle in the air measurement of the lip, and the principle of fluid mechanics is used to generate a one-way pumping effect with a backflow effect.

It is related to the rotation direction of the shaft. Due to the backflow effect, the radial force is smaller than that of the ordinary oil seal, which reduces the wear and heat generation, and improves the service life.

Pressure-resistant NY

The lip is short, the waist is short and thick, and it has the function of pressure resistance, and the working pressure is less than or equal to 3MPa.

It is suitable for occasions where the medium pressure is less than or equal to 3MPa, and is suitable for the shaft end oil seal of the high-pressure pump. Generally, the PV value is less than or equal to 8. Rotation axis speed≤15m/s

Copyright © CBong® Seal All Rights Reserved | Sitemap |Powered by